Advanced water flow rate measurements beyond EN 16430

The performance measurements of trench convectors are regulated with standard system temperatures in the standard EN 16430. The measurements need to be taken under real-life conditions and are intended to permit comparisons between different manufacturers at the design stage.

However, there are shortcomings to this as the standard does not realistically allow for physical drops in output at low water flow rates due to altered system temperatures. We explain below what this means for the design of a trench unit and why Kampmann is working with an advanced measuring process and so can provide you with reliable advice at all times. First up, an explanation of terms.

What is the water flow rate?

The water flow rate indicates how much water flows through a defined pipe cross-section over a specified time. In building services, you might ask: what is the water flow through an air conditioning system over a specific time? This value helps to determine the output of the unit and is given in l/h.

EN 16430-compliant design

Let’s now look at a simple example to briefly illustrate what we mean. Let’s assume a room with a volume or 15 m2 with a cooling requirement of 80 W per m2. The room thus requires a unit with an output of 1200 W. If the trench unit is designed in compliance with the system temperatures specified in the standard EN 16430 and a unit is found that produces 1200 W, then the required room temperature will be met.

However, in practice, the required system temperatures often deviate from the standard. EN 16430 provides a calculation method for this, but it is imprecise in certain areas. The output of a unit actually achieved in practice can often deviate from the calculation methods specified in EN 16430 particularly with low water flow rates. Ultimately, there is a risk that the temperatures required in the room might not be met.

The stand-alone calculation precisely in accordance with the standard often does not apply in practice and does not meet the requirements of the project. While many manufacturers simply convert the values and take into account the imprecise figures of the standard, as the market leader, Kampmann applies an advanced measuring process called DOE (Design of Experiment). This measuring procedure goes far beyond the measuring specifications of the standard.

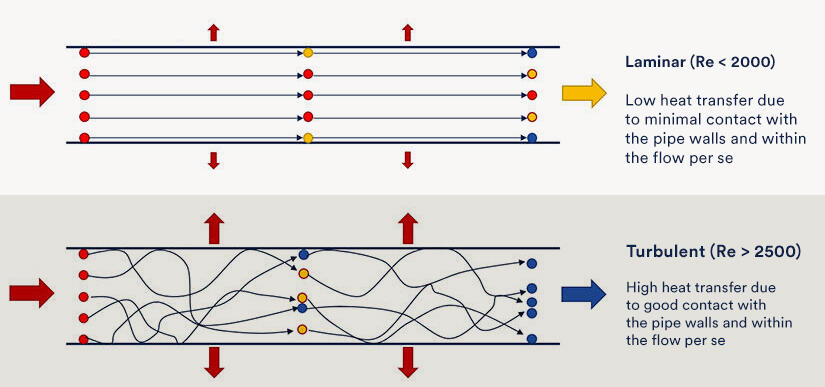

By expanding the measuring range, Kampmann is able to measure aspects, such as laminar flow caused by low water flow rates, which are not taken into consideration in the standard, but are required in projects. This is important in order to be able to provide reliable and practical design data even in areas that are not well covered by the standard.

What is a laminar flow?

No turbulence is (yet) visible in a laminar flow. The water flows in layers that do not mix with each other. At the same time, a laminar flow through pipework leads to significantly lower output. Some turbulence is actively called for. In turbulence, the water molecules have more contact with the inside wall of the pipe and are able to more easily transmit heat to the heat carrier.

There can be deviations and thus efficiency losses of up to 20 % compared to the standard particularly with low water flow rates. If the project is designed in accordance with the standard, this 20 % will subsequently be missing. Output deviations are now a thing of the past with the measuring results integrated in our design programs. It means that you have the certainty of including reliable data in your design and understand at what point the equipment is most efficient in terms of output and turbulent flow.

The measurements are carried out in the Kampmann air flow lab, a key area of the multifunctionally equipped Research & Development Centre (FEC). Thousands of results are combined to provide precise output data for all our units’ water flow rates. They give you design certainty even in areas where EN 16430 is only capable of providing imprecise performance data.

Optimum water flow rate design

Due to the myriad measurements undertaken in our R&D Centre, we are regularly making enhancements to our Katherm trench units in order to achieve optimum flow rates by improving flow through the convector.

Beneficial at the project planning stage too: we can provide the optimum water flow rate at a specified supply temperature to meet your required heat and cooling output. At the same time, our design program enables you to keep this optimum water flow rate constant at all fan speeds and so delivers the correct performance data for your project.

Measured results integrated in calculations programs

The results of our exact water flow rate calculation are integrated in Kampmann design programs. The benefits for you: these calculation programs are easy to use and freely available. As a further aid, we have now included warning information should you be working with low water flow rates that could lead to lower efficiency.

Calculating performance data based on optimum water flow rates provides greater transparency and improved market data. The user-friendliness of our calculation programs is undisputed and we are gradually increasing the number of them. Exact performance data even at system temperatures outside of the remit of the standard is your guarantee for the reliable performance, efficiency and sustainability of your products in operation. Our calculation programs give you the assurance that you will obtain the stated performance, regardless of your design criteria.

Find more design information here. Your Kampmann contact is available for a personal consultation regarding the practical design of specific projects.