Flexibility for an individual climate of well-being

Kampmann supplies a wide range of Katherm trench systems, which have already been installed in innumerable projects. We are one of the market leaders in this sector and can look back on decades of experience. We adapt heating, cooling and ventilation products perfectly to the interior architecture, creating a comfortable climate of well-being.

We would like to briefly clarify a question before concisely presenting the wealth of possibilities and variants available with trench technology:

How does trench technology work?

As its name suggests, trench technology is accommodated within the floor or raised floor. Depending on the trench technology version, they heat or cool the air in the room. The air rises through the heat carrier (convector or coil), creating a comfortable indoor climate. Apart from heating a room, trench technology can also be used to screen cold air in front of large areas of glazing, preventing them from misting up. Trench technology provides effective temperature control, at the same time blending seamlessly into the overall interior design. The units are available in a range of dimensions and with different functions.

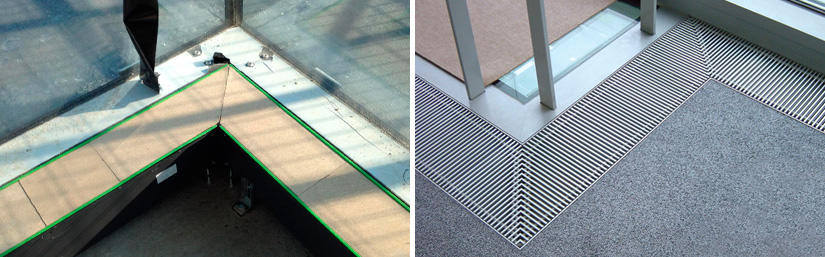

Once the trench system has been installed in the floor, the convector trench is stylishly covered by our metallic aluminium, brass and stainless steel Optiline roll-up or linear grilles. They can also be finished with decorative wooden grilles.

Wide range, ideally adapted to the architecture of the building

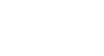

We have a wide range of trench technology versions available. Our focus is on answering your questions: What are the options for adapting these units to the architecture of the building? Click here to find out more about our individual system models.

The following variants are showcased:

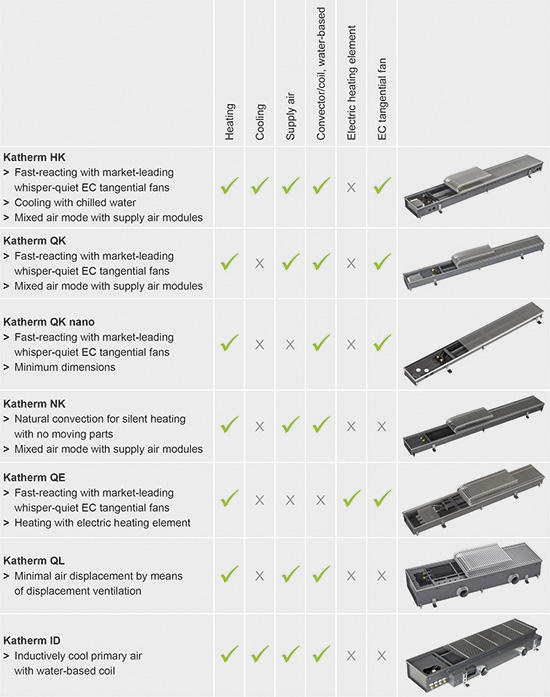

- Special designs, including mitred corners, curved models or cut-outs to fit around columns

- Connecting modules

- Design grilles and a range of styles

Wide-ranging models for larger projects

A high degree of flexibility is called for when it comes to the interior design of large building projects. Special designs, where the trench system is customised to meet the client’s needs, are essentially the norm here. Kampmann is able to supply Katherm trench technology for all building geometries incorporating mitred corners, curved models, cut-outs to fit round columns and angled sections. This enables them to be installed with ease into even tricky situations. Our specialists also attend site to take dimensions. Take a look here at the many possible options.

Project reference: recess with cover plate

The trench technology on site is interrupted by a façade element protruding inwards. Both sides of the element are enclosed by a cover plate.

Project reference: mitre

The products are packaged as best as possible. The mitred trench units are delivered as standard with a plastic cover for the frame edge to protect it during the construction phase (shown green in the photo). A wooden protective installation cover also protects the trenches from dirt and damage during ongoing site work. Compensating for a different floor construction is not a problem either.

Project reference: column recess

Columns positioned directly in front of glazing do not present a problem for the installation of trench heaters. This is solved either by means of a cover plate fitted on both sides or by cutting a recess for the column in the grille itself.

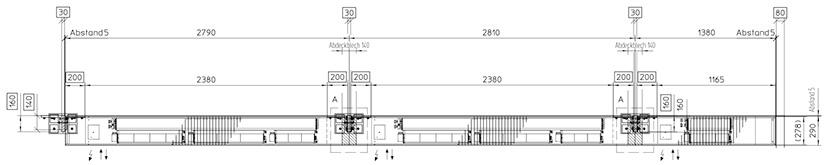

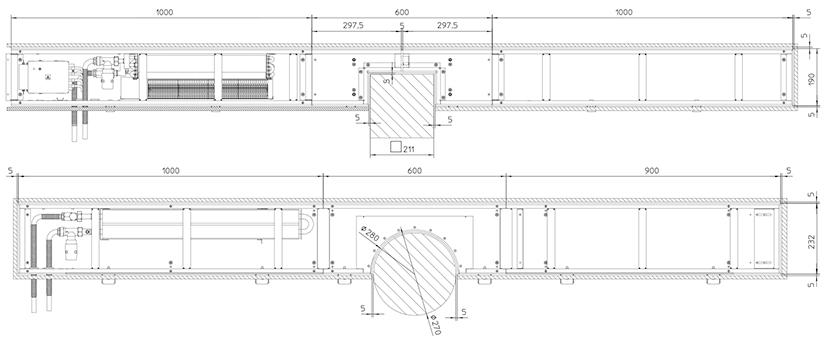

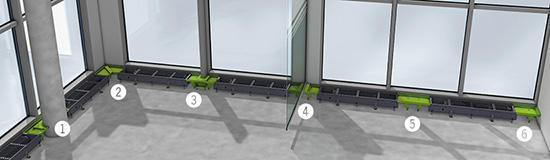

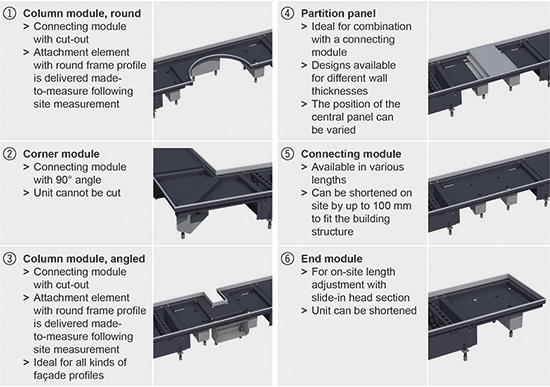

Connecting modules for greater flexibility

Kampmann complies with the architectural requirements, creating an aesthetic overall design without troubling interruptions. Standard connecting modules can be used to flexibly adapt Katherm trench systems to the structural situation on site without the need for prior site measurement. The units can be customised on site with a few simple adjustments. The customer therefore benefits from shorter lead times and faster installation on site.

The following images showcase the wealth of options and show the connecting module that can be individually adapted on site.

Wide range of design grilles and a range of styles

Kampmann grilles come in a range of high-quality materials and fit perfectly - even around curves, mitres and angles. They are able to meet different demands in terms of load-bearing strength, functionality and design. The interplay of grille and frame ultimately delivers a uniform overall picture and optimum adaptation to the building architecture.

The following grille finishes are available:

Roll-up and linear grilles

- Aluminium, natural anodised, brass anodised, black anodised, bronze anodised

- Aluminium, bronze finish,painted DB 703

- Brass, natural CuZn 44

- Stainless steel, natural, polished

Wooden grilles

- Oak, beech, merbau or maple, with a natural lacquered or oiled finish

Matching frames, in the same material and finish, are available for all grilles.

A little cost-saving hint: Kampmann products are synonymous with durability. Simply turn over the grilles. Both sides of the grilles can be used – and the grille looks like new again.

Our project department can assist with your forthcoming project. We will get the maximum performance from the system, even if the design involves the installation of various Katherm modules with different functions. We can design the systems and adapt them to the geometry of your building. We can also perfectly prepare logistics to site and on site. All boxes are precisely labelled to ensure that every planned position can be clearly assigned to every unit – with everything naturally sorted by floor. Simply get in touch with us. Find your individual contact here.

You will also find a wide range of planning support tools, including calculation programs, BIM data and CAD drawings.