How can industrial premises avoid using gas for heating?

How should you heat a hall or shed properly? What aspects need to be taken into account to provide low water temperature-based air conditioning with heat pumps, at the same time avoiding the risk of draughts? We clarify these and other questions using a calculation example and simulations carried out by the Kampmann Research and Development Centre (FEC).

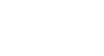

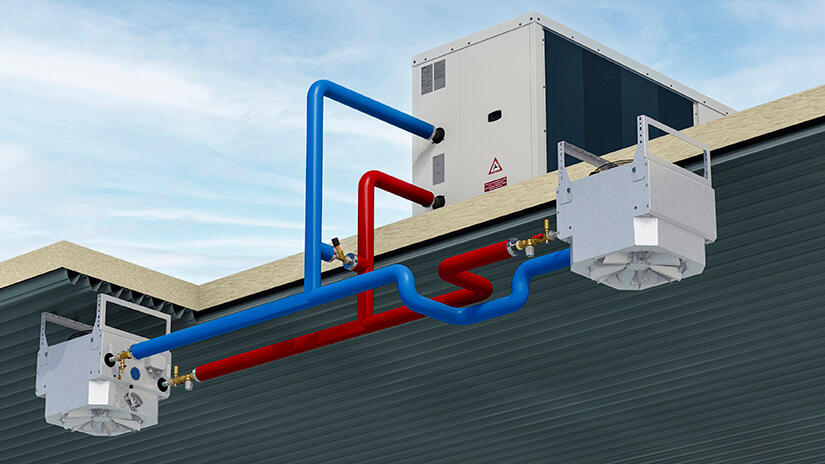

One answer ahead of time: We recommend the use of unit heaters. They are a modern technical solution and are used in a wide range of applications. In order to plan and design a hall or shed correctly, it is important to know in advance the exact use, dimensions, and different climatic conditions in the space. The system should then be designed to meet specific heating, cooling and ventilation needs, including efficiency and comfort requirements.

Different types of use of halls and sheds

A pure warehouse with a constant temperature of 5 °C needs to be designed differently to a hall or shed in which people spend time. This is where the Workplace Directive comes into effect, which stipulates that, where possible, the occupied zone of a building needs to be air conditioned to 17 to 20 °C. Cooling is needed in a production hall with a high heat load, as the Workplace Directive prescribes that the maximum air temperature in workspaces may not exceed 26 °C. Halls and sheds in the logistics sector also feature wide doorways, which can either be mainly closed, or otherwise regularly open to allow goods to move in and out. We recommend the use of air curtains here, as this results in a much lower infiltration rate and counteracts the escape of conditioned air through the doorway.

Low-temperature hall and shed heating

Developers and designers need to determine a wide range of criteria in the correct design of a hall or shed. They might include:

- Geometry of the hall or shed

- Internal thermal sources or dips

- Heat capacity

- Insulation

- Use of renewable energy sources

- Minimised CO2 emissions

- Investment and follow-on costs

The heat load is determined according to DIN V 18599 and DIN EN 12831-1. A target temperature of, for example, 18 °C can be used for the room temperature in the occupied zone. However, the temperature stratification cannot be ignored when determining the room temperature, as experience has shown that as the temperature increases with the increasing hall height, the air movement in the hall is further reduced.

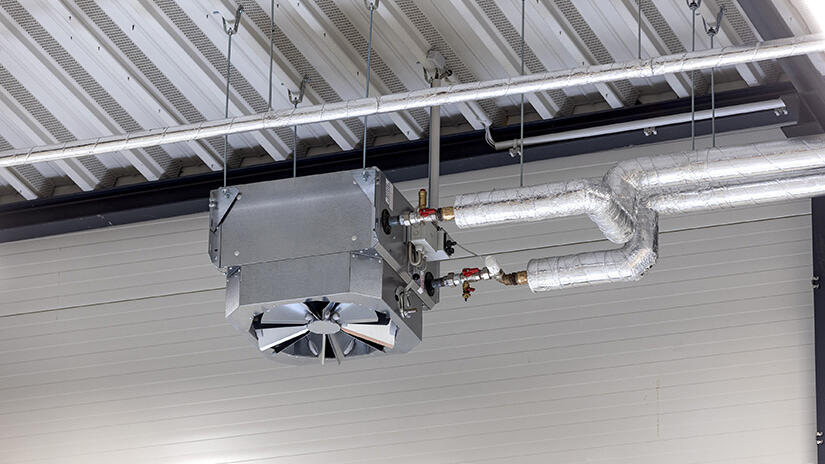

When correctly designed, halls heated with low water temperature-based unit heaters and a heat pump provide adequate air circulation, avoiding heat accumulating under the ceiling. With numerous small units, the temperature is also distributed more favourably, the air speeds are lower, and less noise is generated. This provides comfort with the absence of draughts right down to the occupied zone.

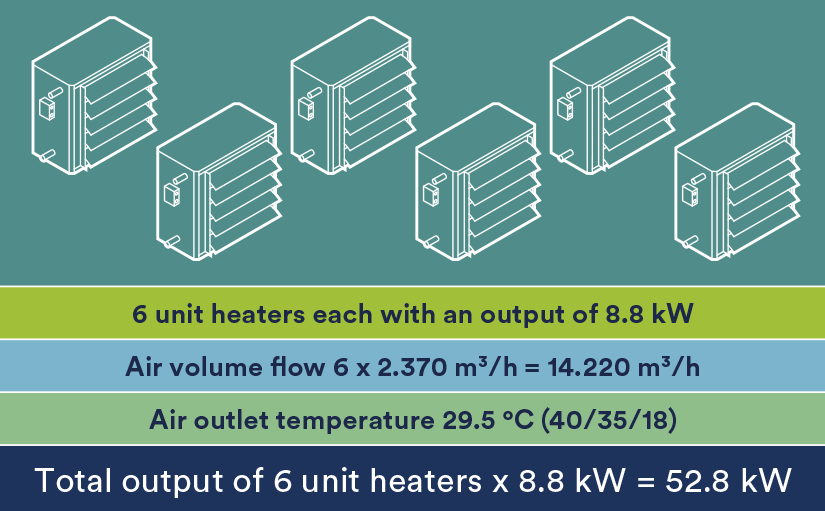

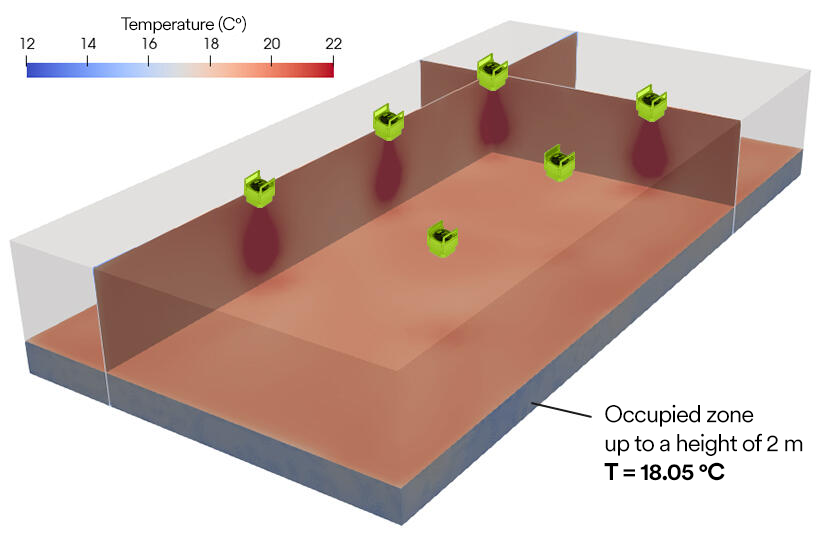

With a calculated heat load of 50 kW in our example, 6 unit heaters are needed, each producing 8.8 kW, in order to achieve a temperature of 18 °C in the occupied zone.

Numerical simulation of the temperature change in the hall

Numerical simulations can be used to map large and complex air conditioning systems to answer customers’ questions with analysis.

The outside temperature in the simulation is -12 °C. The operation of unit heaters in conjunction with heat pumps was tested. We ignored the impact of the doorways in our calculation and simulation models. It should be noted here that air curtain systems massively reduce the infiltration rate, i.e. the ingress of cold air, during the heating period.

The simulation of the sample hall shows: Even at an outside temperature of -12 °C, the low water temperature-based unit heaters nonetheless achieve a hall temperature of more than 18 °C.

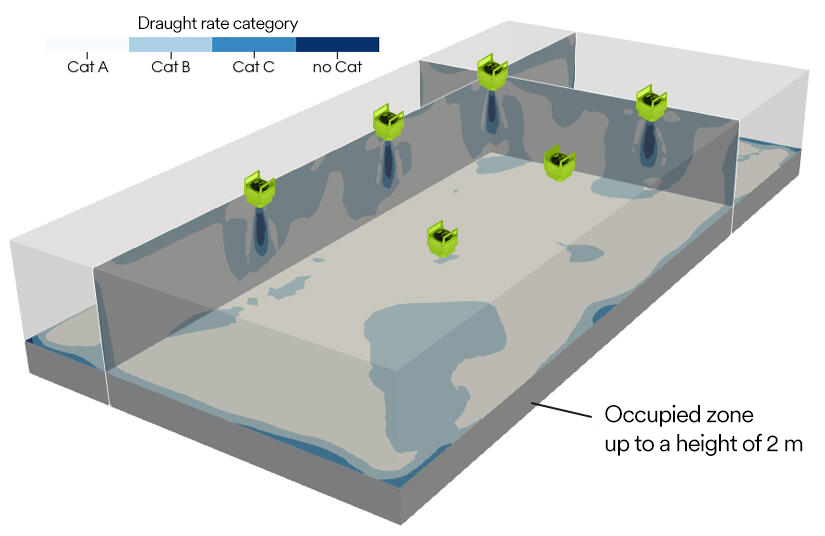

Simulation of the draught risk in the occupied zone

The simulation provides a closer look at comfort levels in the occupied zone. The cross-sectional diagram below shows that even with a discharge temperature of less than 40 °C, that is below the body temperature, there are no problems with comfort in large parts of the hall in accordance with DIN EN ISO 7730. There is only a minimal risk of a draught just below the unit heaters. However, this can be ignored as we are only focusing on the occupied zone.

Simulation result: No risk of draughts in the occupied zone.

Can unit heaters in a hall or shed also provide cooling?

Cooling also needs to be provided when designing a hall or shed with a high heat load. This is important in process engineering, for example, to ensure seamless production. A pleasant and comfortable room temperature also needs to be provided for the people working in the space. Selection of the right units and the correct system temperature provide the solution here.

The air flow also needs to be considered in the design. Cold air "falls" from the ceiling of the hall. This creates hot and cold areas, with the latter often perceived by employees as being too cool or draughty. TOP C unit heaters can be a solution here. These units are all-rounders for the heating and cooling of halls and sheds of all kinds in storage, production and retail. These units are fitted with a condensate tray and are set up to introduce cold air horizontally into the space as well. Ultra unit heaters also have a cooling function and have been developed as ceiling units to provide heating, cooling and ventilation in large, high-end spaces.

The use of unit heaters is future-proof

In today's world, it is important to exploit the potential for energy saving. You are setting yourself up well for the future by installing unit heaters. They are water-based and do not consume gas, unlike infra-red or gas-fired heaters, which are directly fired by gas. Above all, the use of unit heaters combined with a heat pump is environmentally beneficial, as only small amounts of refrigerant are required within the heat pump and the electrical energy will increasingly come from environmentally-friendly generation in future.

Are you considering the use of a heat pump in future but need advice on how to correctly design it in conjunction with unit heaters? Your personal contact will be able to answer this and all other questions.